The condition of our infrastructure is critical in some places. There is an acute need for action to maintain traffic safety and stability, especially on bridges.

At the University of Luxembourg, destructive component tests are carried out on original bridge sections. It has been shown that deformation is a suitable and, in the case of prestressed concrete bridges, the most effective parameter for determining the condition of the structure.

The use of suitable measurement technology can significantly improve and simplify the assessment of the stability of bridges.

To this end, we have developed a measurement method that allows the load behaviour of bridges to be recorded with high precision and deviations from the standard behaviour to be detected at a very early stage.

We use the laser system for dynamic laser measurements (DLM system) to record dynamic displacements at defined points.

The DLM system is characterised by its high temporal and spatial resolution.

With a sampling rate of 50 Hz, we record deformations over distances of up to 100 m in the tenth of a millimetre range.

Deformations caused by traffic loads are thus recorded with high precision. Structural damage becomes noticeable through a change in load behaviour as a result of loss of stiffness and can be detected at an early stage.

Laser measuring track

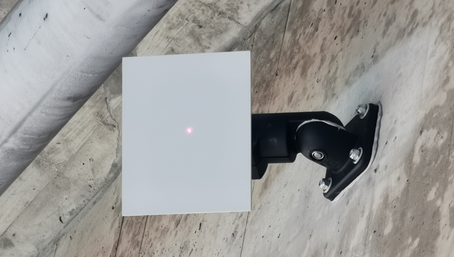

The measuring principle is a permanent laser distance measurement to an inclined measuring target at the measuring location. The displacement at the measuring location is recorded dynamically from a fixed point.

A measuring distance consists of a measuring target and a laser distance sensor. Depending on the orientation of the measuring target, the deformation at the measuring point is recorded in the X-Y or Z direction.

Layout of the measuring sections

In the application, several measuring sections are operated in parallel so that deformations or changes in position at the measuring points are recorded simultaneously at several points.

Temperature compensation is carried out via reference measuring sections with which the linear expansion in the Z direction is recorded in absolute terms and compensated for the measured values in the X and Y directions.

The DLM system was developed for monitoring the condition of critical load-bearing structures. Experience to date has shown that the laser system can be used to record not only changes in condition or reductions in stiffness as a result of damage, but also live loads with high accuracy.

Structural monitoring

During destructive load tests on prestressed concrete beams at the University of Luxembourg, it was found that failure of the tendons is detected very early via the load behaviour - long before cracks become visible on the concrete surface.